Is hose home bathroom water inlet pipe suitable for all types of water source pipes?

Hose Home Bathroom Water Inlet Pipe plays an important role in a home bathroom by connecting the water pipes to bathroom...

|

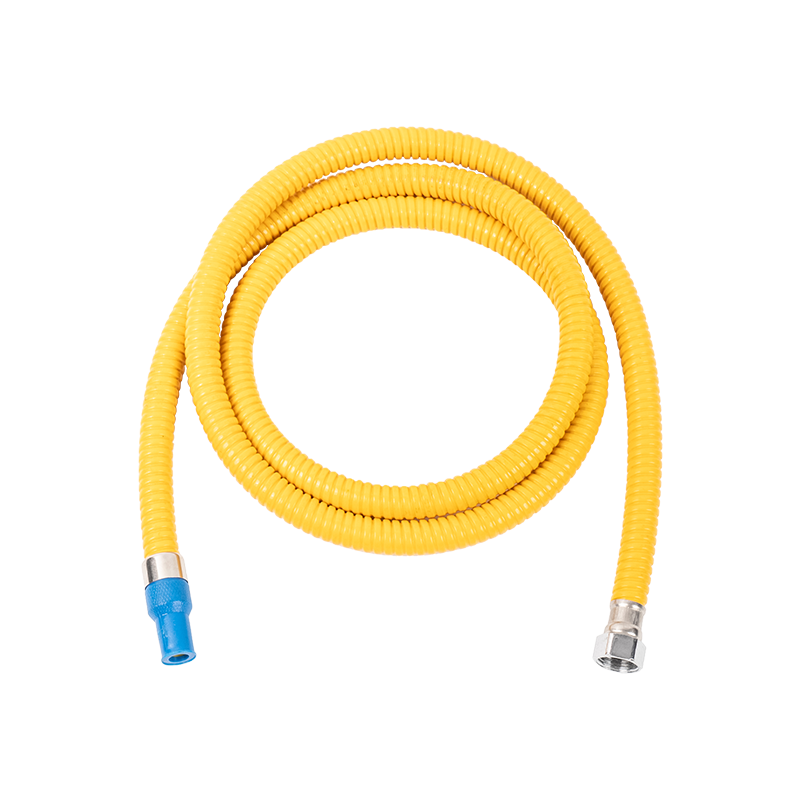

Length |

1.5m 1.7m 2.0m (can be customized) |

|

Tube outer diameter |

18mm (customizable) |

|

BRASS NUTS/BRASS CORES (can be customized) |

|

|

Outer pipe material |

PVC + galvanized metal |

|

Inner pipe material |

stainless steel |

|

NUTS |

LONG NUTS (customizable) |

|

Working pressure |

≤0.05MPA |

|

Perforation requirement |

>23mm |

|

Applicable interface |

9-13mm |

|

Packing |

Transparent plastic bag, hanging card, color box, blister packing (can be customized) |

Yuyao Chaoshun Sanitary Appliance Co., Ltd. was established in 2000. It is famous China 2.0m extra-long gas pipe bellows armored household LPG natural gas gas pipe Suppliers and Custom 2.0m extra-long gas pipe bellows armored household LPG natural gas gas pipe Company, specializing in the production of various metal hoses, metal braided pipes, PVC pipes and various high-end plumbing and sanitary ware. It borders Ningbo City in the east, Hangzhou in the west, and faces Shanghai across the sea in the north. So the transportation is very convenient. It is only about 1 hour away from Ningbo Airport or Hangzhou Airport, and about 2 hours away from Shanghai Airport via Hangzhou Bay Bridge. The existing factory area is 8000 square meters.

Hose Home Bathroom Water Inlet Pipe plays an important role in a home bathroom by connecting the water pipes to bathroom...

Ensuring the durability and stability of the Colorful Stainless Steel Shower Hose color is an important aspect that requ...

During the daily use of bathroom fixtures, shower hoses are frequently manipulated and exposed to a variety of factors i...

The influence of PVC tube wall characteristics on fluid resistance is mainly reflected in the smoothness of its inner wa...

Choosing the appropriate installation location is crucial to the safety and effectiveness of PVC Flexible Silver Wire Sh...

To ensure the reliability and durability of galvanized pipes, proper maintenance and care must be taken. Regular cleanin...